Trigger pull weight reduction.Back to Kel-Tec stuffinstructions originally posted by Blackhawk here Before you begin even reading this you should be able to disassemble your P-11 (instructions for that here) and be familiar with the parts that will be referenced in the instructions (also here) . The normal P11 trigger pull force (on new p-11's) is 8.5#. Shortening the trigger length reduced that to about 7.5#, and this adjustment will reduce it further to about 6.5#. The objective is to effectively shorten the distance between the two ends of the trigger spring so it doesn't require as much force to fire the pistol (ie less force to pull the spring).

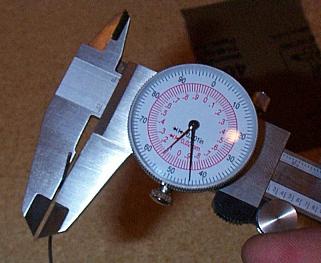

The stock hammer spring pin is .11 inches thick (at least mine was) so the top of the inside of the loop of the hammer spring is .11 inches above the seat where the spring pin rests in. That leaves .075 inches to drop the spring below the seat. you want to end up with a length of wire with a V bent into it where the inside bottom of the V is .075 inches below the bottom of the cross bars.

Reassemble the pistol. Reducing the trigger pull has the effect of lowering the force the hammer applies to the firing pin. Obviously, if that force is too light, the firing pin spring can prevent an effective ignition strike on the primer. The firing pin spring has the job of preventing an accidental discharge since the hammer rests against the firing pin and it's always preloaded by the hammer spring. I highly reccomend smoothing the firing pin, and firing pin set screw, and thoroughly cleaning it occasionally (maybe every 1,000 rounds or yearly) to make sure it stays clean and does not introduce light strikes. Complete instructions on smoothing the Firing Pin can be found here I no longer reccomend shortening of the FP spring for any reason. For more on that see my origonal FP spring page and Drop fire page. | ||||||||||||||||||