SmileysBack to Kel-Tec stuffThis was first discovered in the P-3AT. It was found that the bottom of the feed ramp was contacting the nose of a feeding round, and that this contact was causing a mark on the nose of a round in the chamber. This was also found to be evident on the follower (from the feed ramp hitting that as well while cycling the last round). It was later also found to be occurring in the P-32 as well, but due to lower pressures, and smaller round, no problems ever arose from it in the P-32 (heck no one noticed). There are 2 factors contributing to the cause of smileys.

These 2 things create a head on collision between the nose of the round in the mag, and the bottom of the feed ramp. This is bad for 3 reasons.

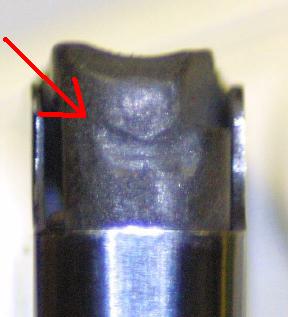

Here are a few pics showing the nose deformations (taken by kevco on KTOG):

Here are a few pics showing Set back (taken by kevco on KTOG):

Here you can see the follower dammage:

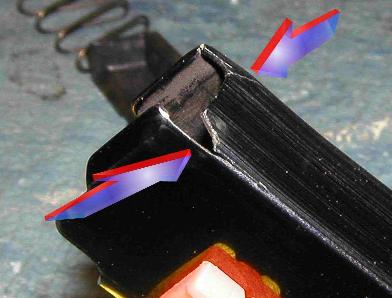

Here is one severe case where the cracks got so bad that the mag failed and the follower was able to to come out the top of the mag.

Here is a mag with only slight contact dammage at the rear top tips (small shiny spots):

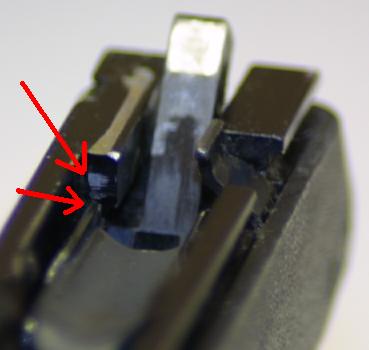

Here you can see where top rear of the mag (bottom arrow) is contacting the frame at the rear of the mag well opening (the mag is slightly dropped to show the contact area).

The feed ramp mod (created by Flyer seen here and here), cuts the bottom portion of the feed ramp, so that it will not extend into mag well area and contact the nose of the feeding round or the follower. Flyer Recommends needle files for this, but I don't have his kind of patients, and have done the same thing on 2 barrels with a dremel, using 2 different stones (starting with the most course) and finishing off with some 400 grit sand paper and then back to the dremel with the felt bullet tip and some polishing compound. But if you don't trust yourself with the dremmel, don't blame me if you leave a few streaks across it when it gets away from you. I will tell you though that it does help (either way) to have the barrel clamped down in something. I also noticed something else that may slightly contribute to nose deformations. There was a sharp corner of the frame right where the top of the mag and the tip of the feed ramp meet. This had the finish worn off, which leads me to believe that something contacted it (left pic, red arrow). So I rounded this corner off, so that if a round hits it, the nose will not be as affected as it would hitting a sharp corner (right pic, red arrow).

The ramp mod significantly reduces the smileys, but does not usually eliminate them. The round is still shifting forward, and will still probably hit the bottom of the feed ramp, but when you cut the ramp back, and take the sharp edge off the bottom of it, this contact is less severe, and far less damaging to the round. Also it is worth noting that no one that has performed the ramp mod has reported cracked mags that I am aware of. Here you can see before and after shots (before and after the ramp mod) of how the ramp moves in the frame (the before shots are of my P-32, as I wrote this after cutting my P-3AT ramp, but they are virtually identical and this works for visual purposes). You can see that the bottom of the ramp actually extends into the mag well when the barrel tilts up and goes back when in stock form (as it does when the slide retracts). You can see this for yourself if you wish, just remove the slide and barrel, then put in the assembly pin, and slip the barrel into place. Then work the barrel back and fourth by hand. After cutting my barrel, it no longer extends into the mag well, and will no longer chew up my followers. Before:

After:

Here you can see rounds in the mag from the other angle, and can see that the second round is just up over that corner in the frame, which is right where the bottom of the feed ramp slams back into.

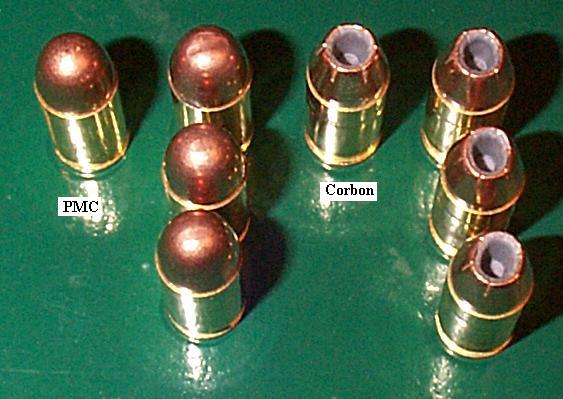

The ramp mod works because the bottom portion of the ramp is not needed, when the round is feeding from the mag, the nose of the round hits at about the middle of the ramp. So that means much of the bottom of the ramp can be totally cut off and not affect feeding. I also choose to just cut the center of the ramp instead of chopping off the 2 sides as well. Others have cut these sides and had no issues, although I prefer to leave them because even though this area is not needed for the feed ramp it is part of the support for the bottom rear of the lug area, and I wanted to leave more metal around the sides to not weaken it more than I had to. While I'm talking about nose deformations, it is also worthy to mention that simply being in the mag while firing is enough to cause nose deformations, due to the rounds slamming into the front of the mag under recoil. I loaded up 7+1 rounds (I have the +1 finger extension) and fired 5 rounds two times, once with FMJ, once with HP's. The top round was in the chamber and the middle round was top in the mag, the bottom was under that one in the mag, the round to the left is a new round.

You can see the HP closing because of hitting the rounded front of the mag, due to the profile of the front of the mag not matching that of the nose of the HP. If you look close you can even see a flat spot on the FMJ rounds from contact with the inside front of the mag. |