Cutting down the P-3AT Firing Pin SpringBack to Kel-Tec stuffThe reason I clipped coils off my FP spring was that I wanted to see if it would fire a round, with a weaker spring, when the hammer only falls from half cock. It did. I also wanted to see if I could find any reason why NOT to shorten the FP spring (the reason why not to in the P-11/P-40 is drop fires due to not having the "half cock" like the P-32 and P-3AT do). I chose to cut 6 coils off because this is the most I could remove and still have the spring push the FP all the way to the rear. Here is what I cut off (top), 2 rounds set off by dropping the hammer from half cock with the shortened FP spring installed (bottom left), 2 rounds set off by dropping the hammer with a full pull and the shortened FP spring (center, showing it is not to much of a FP hit and enough to pierce the primer), and one round fired with a stock FP spring, and a full pull of the hammer (right).

So of course the first thing I did was drop test it. Well I dropped it from 9 feet with a FP spring that had 6 coils clipped off (left), then again from 9 feet with no FP spring installed (right). Both times it did not fire (or come close for that matter). So as I suspected (due to the P-3AT's similarity to the P-32, which I had tested) the P-3AT is more than drop safe.

I personally experimented to see if a slam fire would be a problem in the P-3AT (A slam fire is when the FP going forward with the slide hits the primer of the next round and sets it off when the slide stops its forward movement, basically unexpectedly going full auto). I tried it both with a FP spring cut down 6 coils, and with NO FP spring installed at all. In both cases the pistol was loaded with 2 rounds, one round fired then the one in the chamber looked at for a mark on the primer from the FP slamming into it as the slide comes to a complete stop after cycling a round. With the shortened spring, there was NO mark on the primer of the second round (left pic). With NO spring there was only a scratch on the primer (and if you have ever looked at the round in the chamber of an AR or AK after firing, you WILL see a bit more than a scratch, as they have no FP springs in them either), no where near enough to set one off (right pic). SLAM FIRES ARE NOT AN ISSUE WITH THE P-3AT.

I also experimented with seeing exactly what stops the fp's forward movement if there is no round in the chamber (ie, when you dry fire). If the spring and set screw are removed and only the fp installed, it protruded from my breach face .435 inches (left). If only the spring was installed, when the fp was pushed in until the completely compressed the stock FP spring stopped it, the fp protruded .1815 inches (middle). When the spring was removed and the set screw installed the fp only protruded .0765 inches (right).

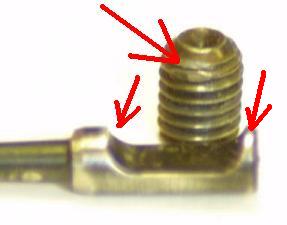

So when the fp is not stopped by the primer, the spring does slow it down, but the rear tab of the FP hitting the set screw is what finally limits the fp's forward movement (right most arrow). Upon closer examination, I see that there is contact evident on the fp set screw (threads deformed), both in the front and the rear from hitting the fp. What surprised me was that on mine the damage to the set screw was mostly on the FRONT side of it (topmost arrow). This is caused by the FP spring pushing the FP back into the set screw (fp hits the set screw in the front at the left arrow). Now if someone has dry fired their P-3AT, I would suspect more thread damage to the rear than mine has (due to when dry firing the set screw stopping the fp's forward movement), but still the same on the front.

There are only 2 reasons that I can think of to not cut down the FP spring. If the hammer ever fell off the hammer block, in stock form, the gun would not go off, but now will. This does not bother me because I have NEVER heard of one instance where this happened. The other reason is that if you dry fire with nothing in the chamber it will stress the FP more because that little tip at the top rear of the FP will be hitting the fp set screw with more force because the FP spring is doing less to slow the fp down (but the primer normally does this, so normal firing is not affected). On the other hand cutting the spring has one large benefit. Now if you mess up and don't let the trigger completely reset (dropping the hammer from half cock), the round will still go off. I would not advise practicing this way (dropping the hammer from half cock) or doing this on purpose much though, as the hammer bock and hammer mating surfaces were not designed to act as a sear and hammer, they were designed only to hold the hammer up and were not intended to slide off each other. Doing this I fear will wear the hammer and or hammer block mating surfaces and cause the hammer to be able to slip off the hammer block. That combined with the shortened FP spring will cause an AD. Other smaller benefits are that: 1) It lessens the impact the FP has on the front of the set screw due to the spring pushing the FP back into the set screw under normal firing conditions. 2) It also makes putting in the set screw easier in that you don't have to hold in the fp while putting it in. 3) And you don't have to worry about catching/finding/holding in the FP while removing the set screw (as it will not be under spring tension). | |||||||||||||